St. Cloud, Minn.

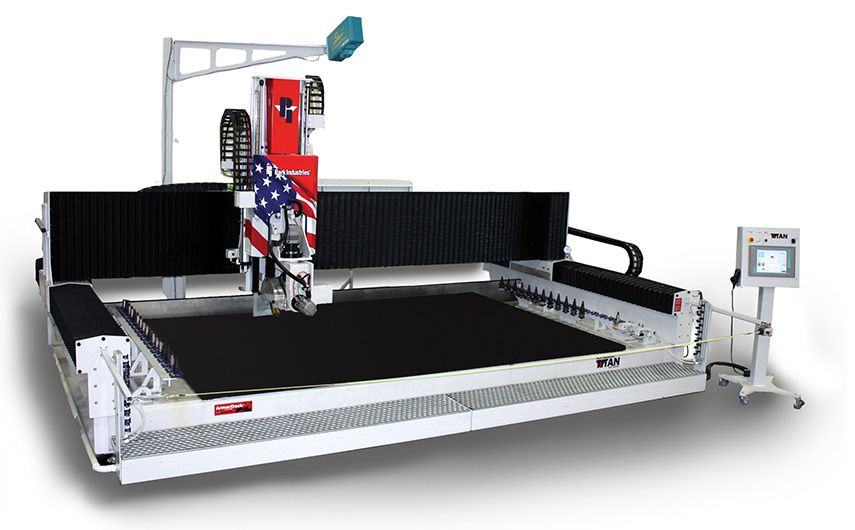

TITAN® CNC Fab Center

Price

Varies based on multiple option selection

Worktable dimensions

Router (Spindle):13’1” x 8’ 1”

Saw (Non-Miter): 11’ 1” x 7’ 3”

Saw (Miter): 11’ 1” x 6’ 9

Production area (X & Y axis travel)

X = 15’ 4 ¾”

Y = 8’ 1 ½”

Z-axis stroke depth

12"

Number of controlled axes for production

5 axes

Maximum thickness of stone to be worked

6cm

Maximum tool diameter allowed

14" blade

Automatic tool changing

Yes

Number of tools in changer/magazine for use

34 with Integrated Tool Management System (ITM), 36 without ITM

Minimum/maximum speed of spindle

Variable up to 10,000 rpm

Spindle motor power

24 HP

Type of controller

Open-Architect CNC Controller

Machines linkable to network

Yes

X&Y axis movement

Rack-and-pinion

Waterjet-head option available

No

North American-based support

Installation/Training

Maintenance

Repair

Main features

4 HP 10,000 RPM Quantum Electro Spindle backed by Park’s 5-year warranty.

CNC servo-driven mitering capabilities (up to 47°) to produce mitered apron edges in a matter of minutes.

User-friendly iTEC Interface technology; intuitive bar-coded system is programmed specifically for your operation for automatic loads and starts.

Integrated Tool Management™ (ITM) system extends tool life by up to 50% and saves tooling costs by automatically monitoring, measuring, and compensating for tool wear.

The unique ArmorDeck work surface holds pieces in place with a powerful suction for greater production speed without parts shifting. In fact, it has 30% better holding power than aluminum surfaces and will never corrode or dent. The unique process produces an aesthetic black finish that impregnates the material for strength and durability. The treatment actually changes the composition of the material on the outside of the part.

OPS Productivity reporting allows analysis of production REAL-TIME, on a daily, weekly, and monthly basis.

Contact

Park Industries

6301 Saukview Drive

St. Cloud, Minn.

800-328-2309

320-251-8126