SFA: What's the Answer?

Blowouts with CNC Sink Cutouts

Vinny

I recently bought an OMAG Digitale 5 with a sink-cutout option. I never had a CNC Saw before, so all this is new to me. I'm having a really hard time figuring out what setting and what incremental bit to use. I'm getting blowout on pretty much every material. especially on ornamental, luna pearl, uba tuba and all quartzite. Does anyone have any advice on which incremental bit to use, what type of setting to try?

Also the difference between soft and hard bond bits? Any help is appreciated. Thanks. Vincenzo Marano Arika Granite

Bradleyg

When I know I'm cutting something that's likely to blow out, I run a 10mm or 12mm non-coring bit instead of a step-cut bit. Set the bit to cut 2mm per pass instead of 1mm and decrease the travel speed to 450. It will take 40% longer to cut corners, but you will get really good corners.

Vinny

Can you tell me which bit you use? I'm using a 20 x 20 soft-bond incremental milling bit. my depth is .096 inches and feed rate is 25 inches per minute. If you change to a 10 or 12 mm bit, then do you have to recalibrate the alignment with your blade?

Bradleyg

On our saw, if you put in the size of the bit in the tools menu it sets the calibration to the blade. We do run the bit a little big. If it mics out to 12mm we enter it in at 12.8mm or so. You might have to play with that a little. Our saw is metric, so the incremental bit is at 1mm cut at 1250mm/minute travel, and the 12mm bit is a 2mm cut at 450mm travel. Just divide these number by 25.4 to get the inches. You’re currently running your incremental bit at a 2.44mm cut depth, which it double what we run ours at. Could be what is causing some of your blowout problems. I think the brand we are currently running is a 1/2" Diamont non coring bit.

Vinny

This is the type of blowout I'm getting with granite.

Express Granite SFA Member

I had the OMAG digitale too. We don’t have any blowout. I can FaceTime you to see my setting. We try few bits no issue. Dennis LI Express Cabinet and Granite LLC. 412-668-0191

Colin SFA Member

That looks like A LOT of bottom-edge blow out for a stone like Luna. We only do sink cutouts on the saw when it’s a hard stone like taj or sometimes when it’s a drop in sink. I just did this drop-in cutout on Bianco Romano. Not as grainy as Luna Pearl but ... see photos.

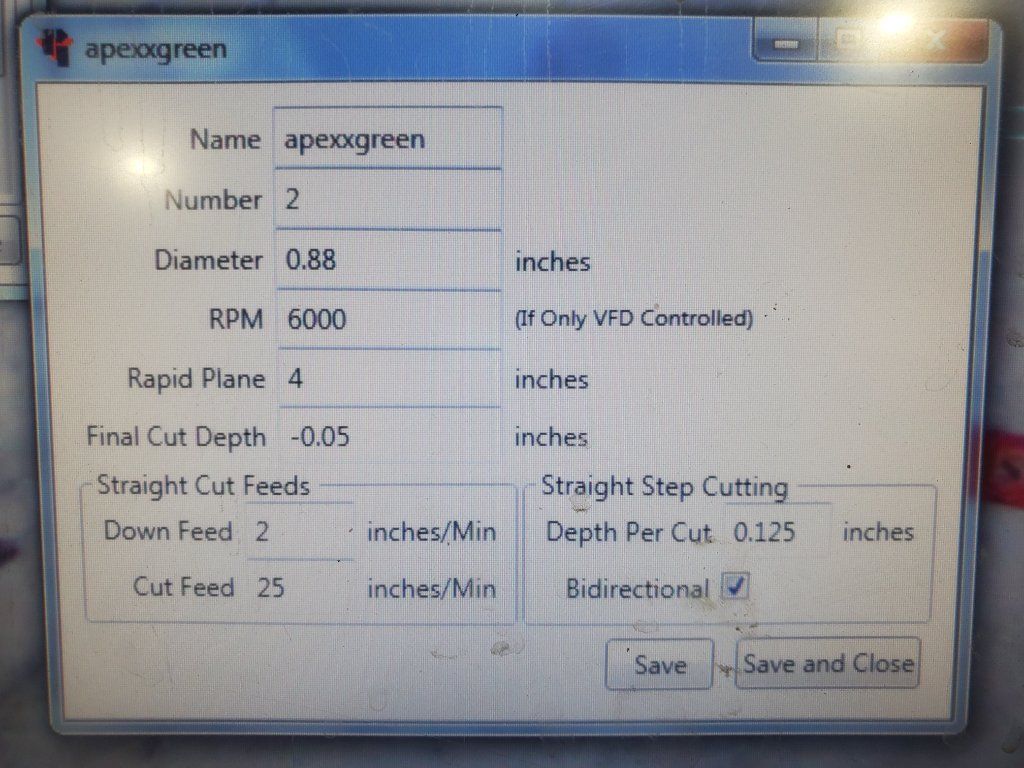

No blowouts really. I’ve attached the table material we use, the tool we use, and the settings for that tool in AlphaCAM. We use the Apexx green bit for ALL STONE TYPES. I have a different setting for Taj type stones, basically half the removal and 2/3s the feed rate.

Oh yeah, I also included the method of pinning the top in place. I used to screw blocks, now for the most part we just use screws.

Colin O'Meara Precision Countertops Spooner WI 715 635 3470 "If I were ignorant I would be happy, but that is not a happiness I desire."-Voltaire

Vinny

Wow, that looks ten times better than my cut out. How long did it take to drop that sink out? Tthis is all new to us since we used to cut by hand before. so my saw guy doesn't know much about rpms or feed rate. If it's ok he might ask a lot of questions. Thanks.

Vinny

My latest blowout on viscount white

Apexx blue bit 20 x 20 RPM 4500 Feedrate 15 ipm Depth rate .04 ipm Does anyone have any suggestions. I just can't figure out why I’m getting blowouts this bad? Are my setting bad? or is viscount white bad material. Any help would be appreciated?

Alex DiPietro SFA Member

Another approach: rather than trying to get the whole overcut, just mill the radius, cut the straights with the blade, use a handsaw to free the piece, and just deal with the blowout in the corners. Alex DiPietro

Vinny

The blowouts are too massive, and the amount of glue I'm using is bad. The job looks horrible, with all the glue.

Colin SFA Member

....Vinny, then take the blade off. I have NEVER used my incremental tool with the blade on. On the Park Saber it takes less than 60 seconds to switch from blade to bit. I don’t imagine its much different on an OMAG. How many sinks/slabs a day are you trying to get through that saw? Is your saw running all day? If not then who cares how long it takes? Another thought-you guys have been doing all hand fab til you got this saw right? Just don’t run the incremental all the way through the slab. Leave an 1/8 or 1/4 and finish it by hand. You are polishing by hand anyway.

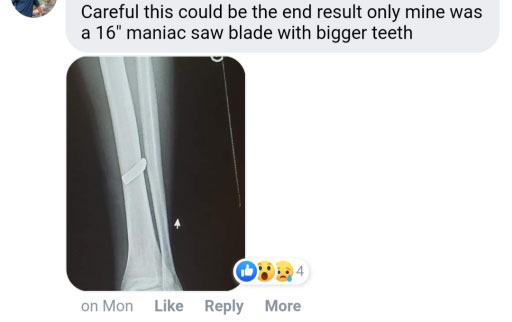

wkluender SFA Member

We cut most of the sinks on our router as it's significantly faster, but when we do cut sinks, the fingerbit is only used for radius cuts. Most kitchen sinks have a straight line that we cut with the blade. If we cut the full cutout with the incremental, that will easily take an hour or more for a 30" x 16" cutout. As far as leaving the blade on while running the fingerbit, that's a hard no. Most blades aren't designed to spin over about 2500 rpm for your average 16". It's a safety issue for me that I don't feel like testing. It's only about 2 minutes of downtime anyhow.

Alex DiPietro SFA Member

No need to take the blade off IMO. Point the blade towards the back of the table. We've been doing it for years.

wkluender SFA Member

This was something posted recently on the Facebook page.

That's a blade segment embedded in someone's arm. Why risk it?

Vinny

I think it's working. Apexx white bit seems to be the key. First time with no blowouts since i bought the machine (2 months) crazy happy right now. White Paradise granite RPM 4500 Feedrate 24 ipm step cut .04 ipm

Just wanted to thank everyone with all the advice.