SFA: What's the Answer?

Drill ¼" Holes for Vertical Wine Rack

JGCSTONE

I have a situation: We installed a 10' piece of quartz vertically inside a custom build wine rack, and that rack was then encased in glass; It turned out really well and looks awesome. Now, two months later, the builder is asking us to drill attachment points for the racking through our stone to the tune of 32 ¼" holes. It will need to be done on site and in the vertical position since the project is so far-advanced. My idea is to use a ¼" blind core bit attached to an angle grinder, but I'm having trouble finding a water system that can work on site and can be used for a vertical application. My thought was to use a Makita PW5001C polisher and trying to retrofit a water connection that could attach to a standard garden hose, then use a sheet of plastic and tape to direct the water flow into a bucket at the base of the cabinet. Does anyone have experience drilling holes in similar circumstances? I'll take any advice before I start purchasing and modifying equipment. Thanks!

Justzack Administrator

I have used a water-fed electric polisher before and used a weed sprayer for the water. Just fill the sprayer and hook it to the polisher. I have also used a hammer drill and I have also used tile drill bit which may be your best option. Test all three in the shop and decide. Justin Zacher Creekside Granite and More 814-657-3294 Justin.zacherl@stonefabricatorsalliance.com

JGCSTONE

Thanks Justin! I thought about the weed sprayer, but my concern was that it wouldn't be able to push water into the hole because the piece is vertical. Maybe I’m overthinking it?

Justzack Administrator

It can push plenty of water. I have used it on Alpha saws before too.

tallzeng Administrator

I have used a water swivel for drilling holes in shower surrounds. The hard part was getting the water to the swivel. I did it two ways. I rigged a hose to the aerator of the faucet and hooked directly to the swivel and I also had a small water pump (like a tile saw water pump) in a bucket hooked up to the water swivel. Both ways worked well to deliver the water to the center of the core bit with no external water needed. I used a hammer drill for the drill.

Keeping the area somewhat dry will be the next issue for you.

GuyboR Administrator

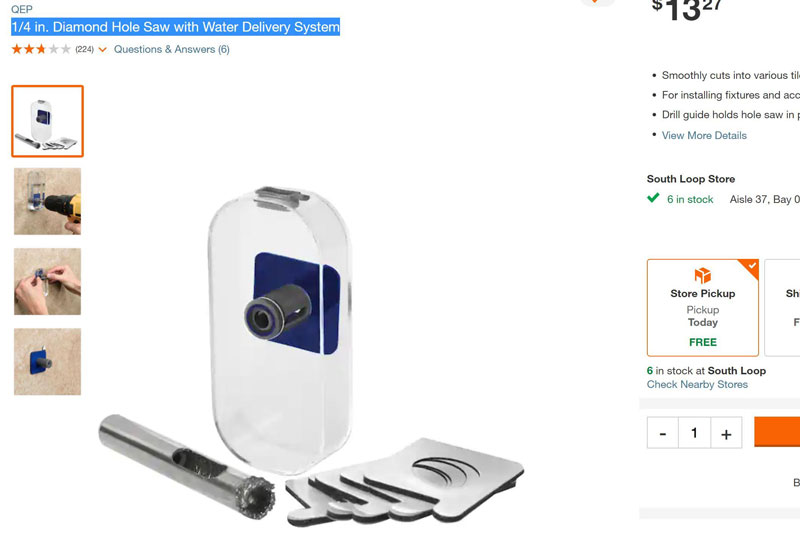

First....never used this. Have only seen it when looking for similar items in the past.

What about this. Guy Robertson Robertson Manufacturing Inc. Davenport, Iowa

gssfabrication Premium Member

Blind-hole bit will work but the hammer drill/tile bit may be easier to drill in place. Did the designer/builder/owner decide after it was put together to put holes in the stone? May not have an issue; however, stone is typically architectural not structural. Hanging wine and racks on the stone looks pretty and likely will not crack under that amount of weight and stress. Putting holes on the sides similar to how nearly every other cabinet is fabricated for shelving must be out of the question or are they putting holes on the sides too? To keep the water/dust from dripping everywhere have someone hold the hose to an empty Shop-Vac under the bit to suck up the water/stone dust combination. Personally, the stone would look better without the 32 holes punched in it and the racks being supported by the sides of the cabinet. They must have a reason as to why they want it this way though. Let us know how it turns out. Rick Graff GSS Fabrication Inc. Richland, Wash. estimating@gssfabrication.com 509-375-1960

JGCSTONE

Rick, that's correct. Our builder requested the job done and never passed along any info about needing the rack mounted to the stone. We did the install and went on our way. Two months later they asked us to figure out how to drill. They had plenty of room to mount to the wood on the sides so I didn't think anything of it.

They want a minimalist look; the rack looks similar to this, if anyone is curious.

David in O.C. Premium Member

The structural statement above is agreed, but if its a must to drill the ¼" holes, quartz is very easy to drill in. We always start with a ⅛" masonry bit to drill the pilot hole with a low impact DeWALT hammer drill, then graduate to 3/16", then to your ¼". Very fast and efficient, no water just a ShopVac with new filter and bag to collect the dust. David at Marbleworks

Matt Lansing Administrator

Danny asks good questions. You don't want the stone being the supporting structure to hold up the wine rack unless you adhered it really well to the substrate to carry that kind of weight. I would just hammer drill the holes. Get a couple of bits, keep them sharp, and it will go fast.

NelsonTile Premium Member

Spade glass bits work great. Just dip in a cup of water to cool a couple times per hole.

bobslusser Premium Member

We drill holes on-site all the time. Spray-bottle of water and a blind-hole bit or tile bit in a drill. Spray the bit as you're drilling and stop every once in a while to spray the hole. Never had an issue in any material. Don't run the bit at 12,000rpm and it works fine. Bob Slusser