Handling Slabs: Know the Shadow

The cost of wayward materials can be measured in dollars, hours ... and lives.

When learning the ins and outs of slab handling in virtually any stone shop, warehouse or stone storage yard, it’s important to understand the dynamics of stone slabs – and why they can be unwieldy and extremely dangerous if not handled properly.

Description of Slab Properties

Size. Natural stone is quarried in blocks that are trucked to a facility to be slabbed, or cut into slices that are typically 5’ X 10’ X 1-3/16” thick (5.5m X 3m X 3cm thick). The oblong dimensions can make them particularly unstable and dangerous during movement in windy conditions in outdoor storage yards. It doesn’t take much of a gust of wind to turn a slab into a deadly instrument. Weight. Slabs are quite thin compared to their height and width. They look deceptively light. However, a typical slab will weigh somewhere between 800- 900 lbs (350-400 kg), and often exceed 1,000 lbs (455kg). When grouped together in a bundle of five or six slabs, the weight goes up to 5,000 lbs (2,200kg) or more. A slab weighing almost 1,000 lbs (400kg) has the potential to create a life-threatening situation in a split second. Balance. One of the keys to avoiding an accident, indoors or outdoors, is to be extremely careful when attaching the clamp to the center of the slab before moving it with a forklift or crane. Moving a poorly balanced slab greatly increases the possibility of tipping and breaking the slab.

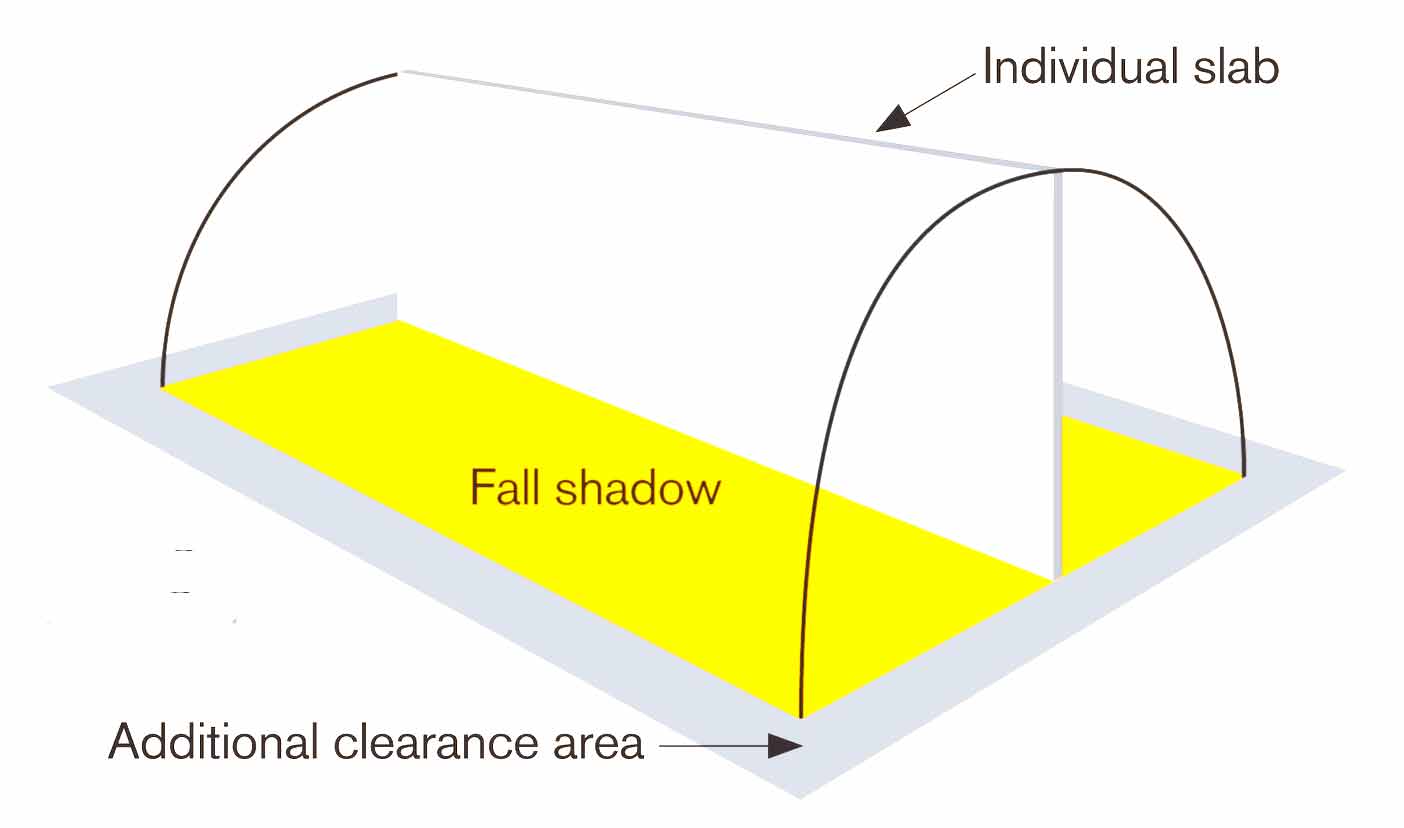

The Fall Shadow

The Fall Shadow is the area on both sides of the slab where it could land if tipped or dropped. Life and limb are in jeopardy inside the Fall Shadow; stay outside the area. The risk of being crushed or hit by stone shrapnel will be greatly reduced. The temptation to simplify a job or task (a workaround) presents itself frequently. Is standing in front or behind the slabs (within the Fall Shadow) to save a few minutes worth your leg … or life?

Proper material handling procedures must be followed at all times. Standing in the Fall Shadow of a slab can result in a crushing injury or fatality should the slab tilt too far.

The temptation to stand in front or behind the slabs (within the Fall Shadow) presents itself frequently. Be mindful of body placement in everyday work situations such as unloading, unbundling, storing, handling, moving or loading stone slabs.

Slab Hazard Precautions and Best Practices

• Avoid manually lifting stone slabs where possible. • Use mechanical aids (slab dollies, suction cups, vacuum lifts, clamps, etc.). Lift only loads that can be safely handled. • Use the proper material handling equipment (e.g., an overhead crane with appropriate approved attachments, a forklift truck equipped with appropriate and approved boom attachments and lifting devices, or other equipment designed to assist slab handling). • Place the clamp on the secure area of the stone when moving and/or lifting a slab. • Placing the clamp over a weak vein can cause the stone to break and fall. Clamps should be used only on solid stones without flaws, open seams, or cracks. • Only use suction cups and vacuum lifts on smooth stone (unless rated to lift another type of finish by the manufacturer). • Do not use scissor clamps on equipment operating on uneven surfaces. • Assure that dollies used to move stone slabs are designed to support the weight of the slab. • Walk on either end of the dolly to support the slab. • Raise the load only as far as necessary to clear the road surface or obstacles when using powered industrial trucks. • Only handle loads within the rated capacity of the truck when using powered industrial trucks. • Remove the supports and bracing from the stone slab bundles inside shipping/storage containers using a sequence that does not allow for the other slabs to shift or collapse. • NEVER lean or tip a slab toward yourself or anyone else when the slab is tall enough that it could hit you or another person should the rigging give way. Keep away by two times the vertical height. Use tag lines when possible to guide slabs during hoisting. • NEVER stand under, near or in the fall shadow of a slab when moving it. • NEVER walk in the fall shadow of a slab. Always walk at the end of the slab.

Photo courtesy Occupational Safety and Health Administration

Reminder: Safety is the responsibility of both management and employees!

All Natural Stone Institute Safety Resources and Courses are offered free at www.uofstone.com and www.naturalstoneinstitute.org/safety.

The information herein is provided by the Natural Stone Institute as a general summary for use in job site toolbox talks and is provided to augment and not substitute for or replace required training under any applicable local, state or federal workplace statute, law or regulation. It is the user’s responsibility to ensure this content is consistent with job site requirements and applicable statutes, laws or regulations prior to use and make any required additions or changes.