Do The Eyes Have It?

Keep Your Protection in Sight for Workers

Photo by Andre Moura at Pexels

Are you in danger of becoming a statistic? Thousands of people are blinded each year from work-related eye injuries that could have been prevented with the proper selection and use of eye and face protection. Eye injuries alone cost more than $300 million per year in lost production time, medical expenses, and worker compensation. https://www.osha.gov/SLTC/etools/eyeandface/ppe/selection.html

Selecting PPE for the Workplace

Personal protective equipment (PPE) for the eyes and face is designed to prevent or lessen the severity of injuries to workers. Employers must assess the workplace and determine if hazards that necessitate the use of eye and face protection are present or are likely to be present before assigning PPE to workers. [29 CFR 1910.132(d)] A hazard assessment should determine the risk of exposure to eye and face hazards, including those which may be encountered in an emergency. Employers should be aware of the possibility of multiple and simultaneous hazard exposures and be prepared to protect against the highest level of each hazard. [29 CFR 1910 Subpart I App B]

Name Your Hazard

Impact

Flying objects such as large chips, fragments, particles, sand, and dirt.

Chipping, grinding, sawing, machining, masonry work, woodworking, chiseling, drilling, powered fastening, riveting and sanding.

Heat

Anything emitting extreme heat.

Furnace operations, pouring, casting, hot dipping and welding.

Chemicals

Splash, fumes, vapors, and irritating mists.

Acid and chemical handling, degreasing, plating and working with blood.

Dust

Harmful dust.

Woodworking, buffing and general dusty conditions.

Optical Radiation

Radiant energy, glare, and intense light

Welding, torch-cutting, brazing, soldering and laser work.

Impact Hazards

Most impact injuries result from flying or falling objects, or sparks striking the eye. Most of these objects are smaller than a pin head and can cause serious injury such as punctures, abrasions, and contusions. While working in a hazardous area where the worker is exposed to flying objects, fragments, and particles, primary protective devices such as safety spectacles with side shields or goggles must be worn. Secondary protective devices such as face shields are required in conjunction with primary protective devices during severe exposure to impact hazards.

Spectacles: Primary protectors intended to shield the eyes from a variety of impact hazards. Goggles: Primary protectors intended to shield the eyes against flying fragments, objects, large chips, and particles. Face Shields: Secondary protectors intended to protect the entire face against exposure to impact hazards.

From the OSHA Files

At approximately 2:30 p.m., Employee #1 was using a pneumatic water/air polisher on a piece of granite. The flexible diamond disc fractured, and a piece struck his left eye. Employee #1 was hospitalized for treatment, and the eye was later removed surgically. The employer failed to ensure that each affected employee use appropriate eye or face protection when exposed to eye or face hazards from flying particles [1910.133(a)(1)]. Furthermore, the employer failed in his responsibility for the safe condition of tools and equipment used by employees, including those which may be furnished by employees [1910.242(a)].

Accident Prevention Recommendations • Train maintenance and operating personnel to recognize potential problems when working with power hand tools. • Have competent persons perform periodic inspections of all operating equipment and PPE. This case was selected as being representative of injuries caused by improper work practices. No special emphasis or priority is implied nor is the case necessarily a recent occurrence. The legal aspects of the incident have been resolved, and the case is now closed.

Safety Spectacles

Safety spectacles are intended to shield the wearer's eyes from impact hazards such as flying fragments, objects, large chips, and particles. Workers are required to use eye safety spectacles with side shields when there is a hazard from flying objects. Non-side shield spectacles are not acceptable eye protection for impact hazards. [29 CFR 1910.133(a)(2), 29 CFR 1915.153(a)(2)] The frames of safety spectacles are constructed of metal and/or plastic and can be fitted with either corrective or non-corrective impact-resistant lenses. Side shields may be incorporated into the frames of safety spectacles when needed. Consider each component of safety spectacles when selecting the appropriate device for your workplace.

Lenses

The lenses of safety spectacles are designed to resist moderate impact from flying objects and particles. • Plano (non-Rx) lenses should be used by workers who do not require vision correction. Lenses may be flat or curved and are available in clear, filtered, or tinted lenses and may include removable lenses. • Prescription (Rx) lenses should be used by workers who require vision correction. These lenses may be clear, filtered, or tinted and may include removable lenses

Piano Lenses

Prescription Lenses

Frames

The safety spectacle frames must fit comfortably and correctly to offer the necessary protection. • Spatula temples fit over the ear, and cable temples fit around the ear. They can be either fixed or adjustable and are available in metal or plastic • Headband temples are easily adjustable for a secure fit and are useful for tasks requiring movement. • Bridges are available in fixed or adjustable types. They may have adjustable nose pads with pliable arms and are available in a variety of sizes

Spatula Temples

Headband temples

Adjustable Nose Pads

Side Shields

Side shields provide angular protection from impact hazards in addition to frontal protection. • Flatfold or semi side shields may be part of, or attached to, the temple. Styles include permanent, removable, solid, ventilated, tinted or clear shields. • Full (cup) side shields may be removable, wire-screen, tinted or clear.

Flatfold Side Shields

Full (cup) Side Shields

Safety Goggles

Safety spectacles are intended to shield the wearer's eyes from impact hazards such as flying fragments, objects, large chips, and particles. Workers are required to use eye safety spectacles with side shields when there is a hazard from flying objects. Non-side shield spectacles are not acceptable eye protection for impact hazards. [29 CFR 1910.133(a)(2), 29 CFR 1915.153(a)(2)] The frames of safety spectacles are constructed of metal and/or plastic and can be fitted with either corrective or non-corrective impact-resistant lenses. Side shields may be incorporated into the frames of safety spectacles when needed. Consider each component of safety spectacles when selecting the appropriate device for your workplace.

Lenses

Safety goggles lenses are designed and tested to resist moderate impact. • Clear lenses are available with removable lenses which may be prescription. They do not provide special protection against optical radiation.

Clear, Removable Lenses

Goggle Frames

Safety goggle frames must be properly fitted to the worker's face to form a protective seal around the eyes. Poorly fitted goggles will not offer the necessary protection. • Eyecup safety goggles cover the eye sockets completely. They are available with direct or indirect ventilation and can be rigid or flexible. • Cover safety goggles may be worn over corrective spectacles without disturbing the adjustment of the spectacles and are available in direct, indirect, or non-ventilated types. They may be rigid or flexible.

Eyecup Goggles

Cover Goggles

Ventilation

Ventilated goggles allow air circulation while providing protection against airborne particles, dust, liquids, or light. • Direct ventilation resists direct passage of large particles into the goggle while preventing fogging by allowing air circulation. • Indirect ventilation prevents fogging by allowing air circulation and protect against liquid or chemical splash entry. • Non-ventilated goggles do not allow the passage of air into the goggle. They prevent splash entry, but may fog and require frequent lens cleaning.

Direct-ventilated Goggles

Indirect-ventilated Goggles

Non-ventilated Goggles

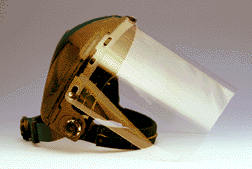

Face Shields

Face shields are intended to protect the entire face or portions of it from impact hazards such as flying fragments, objects, large chips, and particles. When worn alone, face shields do not protect employees from impact hazards. Use face shields in combination with safety spectacles or goggles, even in the absence of dust or potential splashes, for additional protection beyond that offered by spectacles or goggles alone. Face-shield windows are made with different transparent materials and in varying degrees or levels of thickness. These levels should correspond with specific tasks. Window and headgear devices are available in various combinations to enable the worker to select the appropriate equipment.

Windows

Face-shield windows extend from the brow to below the chin and across the entire width of the face. Windows are available in both removable and lift-front designs. • Plastic window-types protect against light impact. They are available clear or filtered and may include a glass insert. • Wire-screen windows protect against some moderate impact. They may include a plastic/glass insert and are not recommended for use involving chemical or liquid hazards.

Plastic Window

Wire-screen Window

Headgear

Headgear supports the window shield and secures the device to the head. • Adjustable headgear includes straps that allow the user to manipulate the size of the headgear to ensure a proper fit. Face shields can be shared between employees • Hard hats with face shields may have a window shield mounted under the visor of the hat. Face shields may be plastic, wire-screen, lift-front, or removable.

Adjustable Headgear

Hard Hat with Face Shield

Other Hazards

OPTICAL RADIATION: Welding, torch-cutting, laser work and similar operations create intense concentrations of heat, ultraviolet, infrared, and reflected light radiation. Some laser beams can produce intensities greater than those experienced when looking directly at the sun. Unprotected laser exposure may result in eye injuries including retinal burns, cataracts, and permanent blindness. When lasers produce invisible ultraviolet or other radiation, both employees and visitors should use appropriate eye protection at all times. Determine the maximum power density, or intensity, lasers produce when workers are exposed to laser beams. Based on this knowledge, select lenses that protect against the maximum intensity. The selection of laser protection should depend upon the lasers in use and the operating conditions. Workers with exposure to laser beams must be furnished suitable laser protection. [29 CFR 1926.102(b)(2)] NUISANCE DUST: Nuisance dust is generated in the stone industry during operations such as grinding and buffing marble and other calcareous stone. Working in dusty environments can causes eye injuries and presents additional hazards to contact lens wearers. Safety goggles are the only effective type of eye protection from nuisance dust because they create a protective seal around the eyes. Wear either eyecup or cover-type safety goggles when dust is present.

Reminder: Safety is the responsibility of both management and employees!

The information herein is provided by the Natural Stone Institute as a general summary for use in job site toolbox talks and is provided to augment and not substitute for or replace required training under any applicable local, state or federal workplace statute, law or regulation. It is the user’s responsibility to ensure this content is consistent with job site requirements and applicable statutes, laws or regulations prior to use and make any required additions or changes.