SFA: What's the Answer?

C-arm Polisher General Settings

Stoneshopinc

I have an old C-Arm machine that has sat idle for many years and am looking to try and get it up and running. General questions in terms of feeds and speeds, and how many passes for each pad. In the little playing I have done with it, it seems to be leaving vertical lines, even though the shine is nice. Any online resources , or if you had 10-20 minutes to chat would really appreciate it!

Gssfabrication SFA Member

Have you tried contacting the manufacturer of the machine to see if they could e-mail you a guide? If you post the make and model of it someone on here probably had or still has that same machine and could give you some input. Rick Graff GSS Fabrication Inc. Richland, Wash. estimating@gssfabrication.co 509-375-1960

Stoneshopinc

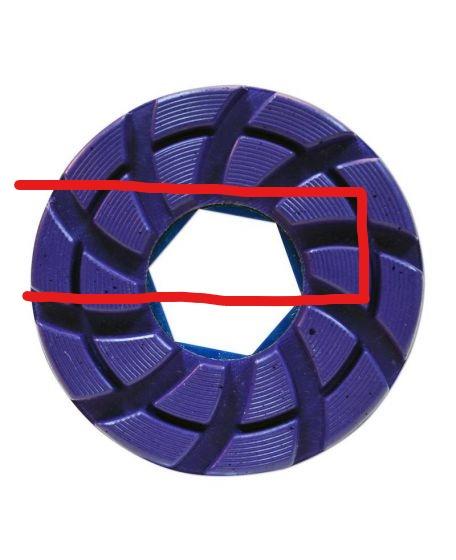

It is a Polish manufacturer (still exists) with the machine being sold through an intermediary that no longer exists. I have the instructions from them but wanted to talk with someone who has worked with a C-arm machine with current pads to see what works best, especially for different materials. Another member suggested talking with pad manufacturers, and said Terminator was very helpful. I have a set of Glossfire pads, and their instructions are to just keep increasing pressure with subsequent pads, but that seems counterintuitive, plus pressures are higher than the manual says for limits. I just played around some more, and what worked on some infinity white quartzite was to use step 1 and step 2 pads (Velcro-backed), and then the weha monkey pads. The problem I was seeing was lines (but nice gloss), and the monkey pads seem to produce a nice result without the lines. Will keep testing. Was reaching out since experience and a person is easier than a manual sometimes.

Wkluender SFA Member

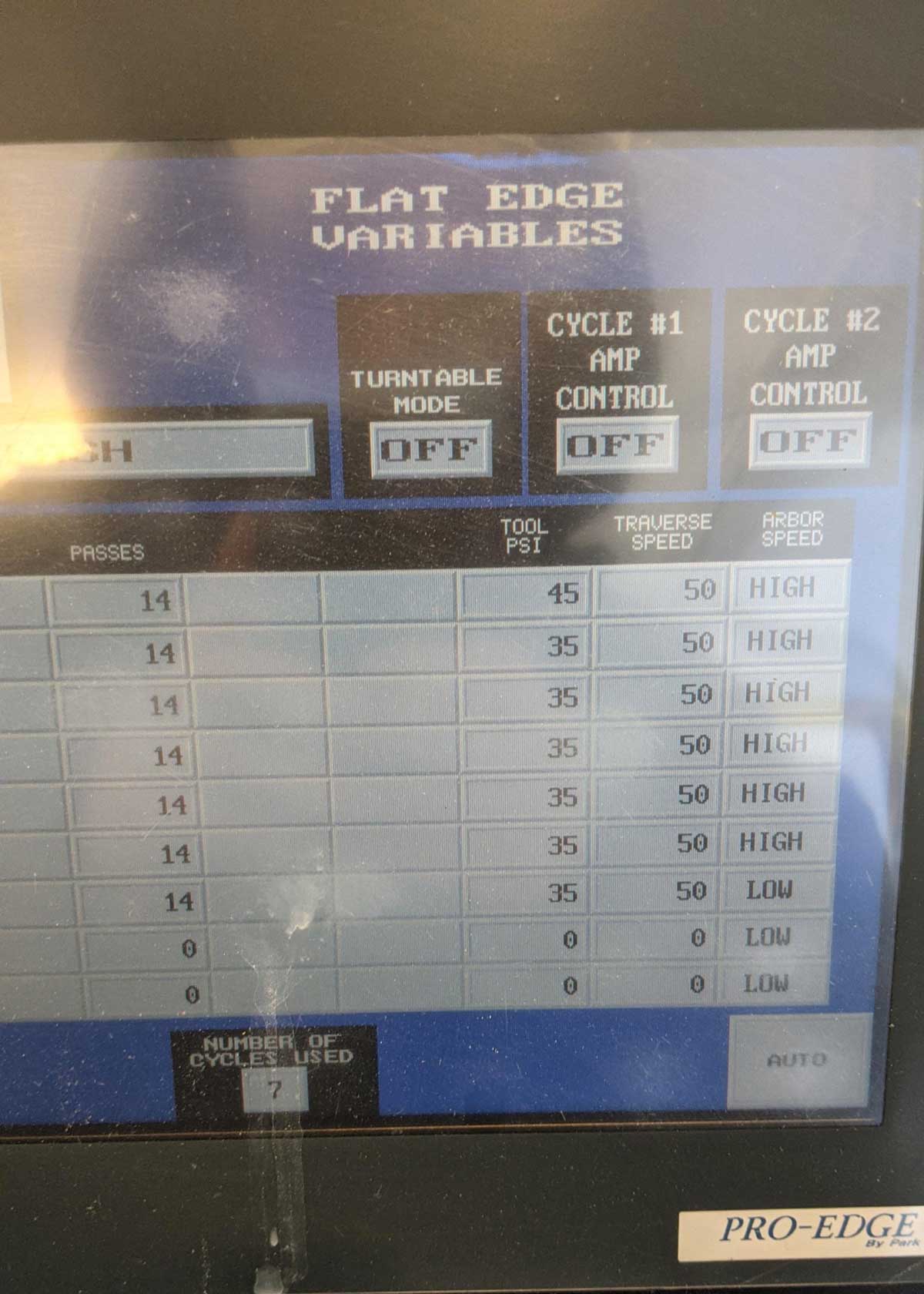

We actually back the pressure off a little on the PRO-EDGE. We run GlossFires for our flat edges as well. I think the first 2 are running at 35 psi with everything else running at 30 or 25. I can't set the rpms specifically as our PRO-EDGE only has high or low for arbor speed options, but the last pad is run with the lower rpm option. Wes Kluender Classic Granite & More Le Sueur, Minn

Stoneshopinc

Thanks! GlossFire actually says to do the opposite! From their tech support - "Starting pressure: 30 PSI or 2 bars linear feed rate: 20-30 inches per minute number passes: 2 passes on flat edge, for round edges: 2 cycles. Spindle 2500 RPM. The setting above are good for all materials. For marble and granite, use all grit sizes including Buff For Quartz and Quartzite stop at grit 2000. " Start at 30 PSI (2 bars) and increase the pressure by 5 PSI (0.3 bars) at each consequent step. For example, if you start with grit 100, you have to set the machine at 30 PSI. For grit 200 – 35 PSI, grit 500 – 40 PSI, grits 1000, 2000 and BUFF – 50PSI Our machine is 2 speeds as well, 3600 and 1800 rpm, they said granite 3600 rpm everything else 1800 RPM. One problem with their instructions is that my machine slowest travel speed (uses potentiometer not programmed) is around 90 linear inches per minute, so almost 3-4 times as fast as they recommend. When you start the polish cycle - how much overlap do you start with the pad on the piece (say 1/2 of pad, 1/4 pad) to make sure the ends get the same polish as the middle? Finally - do you have your machine polish the eased radius top and bottom, or do you just have it polish square, and then have your guys manually ease the edges when polishing is complete? Appreciate the help!

Wkluender SFA Member

So i'll have to check the exact parameters, but I'm pretty sure we run 20 passes at about 60 ft/min (or whatever the metric is the PRO-EDGE uses) for the first 2 grits. We maintain the same feeds over all grits, but the passes drop to either 10 or 12 by the final pad. We also run the buff on everything, regardless of material. I also offset the pad so it's not perfectly centered on the stone. When I set the stops, I make the pad stick out past the upper corner about 1/4" past the center water channel.

Stoneshopinc

If you could check - that would be great! So it looks like more passes, but going faster, rather than fewer passes slower, makes a lot of sense. And then since less material removal, less passes on the higher grits. Very helpful on starting placement as well. Thanks!

Wkluender SFA Member

So I was wrong on our settings. This is what we are running with the GlossFires.

Stoneshopinc

Hi Wes – thank you. Did you ever verify unit? I assume inches per minute if the rate is 50.

Krstech Friends of the Alliance

I used to sell Scandinvent edge polishers with the C arm and setting it up for how many repetitions and at what speed did depend on material. I always approached it like CNC tools that the first tool is going to calibrate the edge or shape it. Next tool has to remove the deepest scratches and make a uniform finish from that grit; each tool after that has to remove the scratches from the previous grit working your way to the final polisher. The pressure was pre-set in the machine.