Fabricator Focus

Alaskan Granite Works Fairbanks, Alaska

"I’ve always been into new equipment."

All photos courtesy Alaskan Granite Works

By K. Schipper

FAIRBANKS, Alaska -- Alec Turner can be a team player. His years climbing some of the world’s tallest mountains proved that. In his stone shop, however, not so much. The owner of Alaskan Granite Works, Turner is something of a one-man band when it comes to selling, templating, and cutting his jobs. Yes, he does have a helper for installs, but then he isn’t above plowing or snow-blowing a path to a customer’s door if the conditions require it. It’s not that he wouldn’t mind having help in the shop but attempts to add a second person haven’t panned out, and he admits Fairbanks isn’t to everyone’s liking. As it is, he’ll just continue to get the most out of his automated equipment.

“I brought in two people from the Lower 48, and both times, this wasn’t the place for them.”

Alec Turner

One-Man Shop

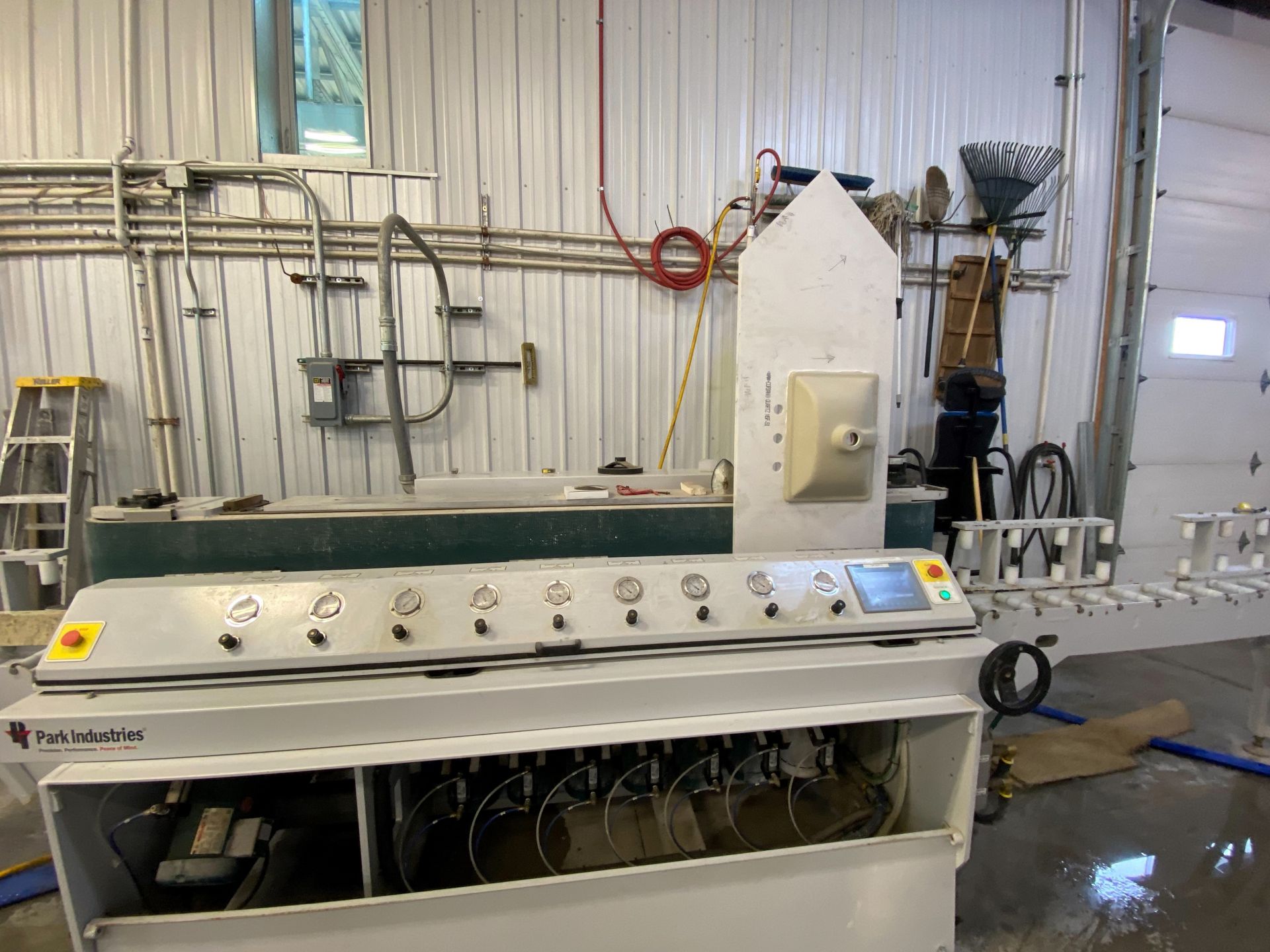

Turner opened for business in 2002, after watching countertops being installed in a home where he was working on the exterior as a siding and gutter contractor. At that point, granite countertops were only just taking off in the Lower 48, and certainly hadn’t reached into Alaska’s interior. Still, he did more than a year of research before changing careers. And the first countertops he sold were fabricated by a source in Seattle, then shipped in. Although shipping still offers challenges that would likely appall anyone not used to living in Alaska, Turner quickly realized he could make money on the fabrication and started buying equipment. He quickly invested in a track saw, and when that proved inadequate, he purchased a Park Industries YUKON® and then added a PRO-EDGE® for polishing and shaping. “I’ve always been into new equipment,” he says, adding that today the shop runs on a Park Industries SABERjet™, a Fastback II®, and a Brembana Micra 2.0 for sink cutouts. “I still have the PRO-EDGE.” Turner makes the distinction because seven years ago he moved out of the warehouse where Alaskan Granite originated and into a new 6,600 ft² facility that includes an 1,800 ft² showroom and bought the new equipment at that time. The new building has helped him keep operating the way he always has – just better. By being more automated, he says it enables him to walk away from production if someone comes in, although he doesn’t necessarily encourage it. “This is a small market, so I just set up appointments,” Turner says. “I’m not going to turn somebody away if they walk in the door, but it helps if I know somebody is coming in.” Part of it is that Turner adheres to a fairly rigid schedule. He measures one day a week, fabricates three days a week and then installs one day a week. It’s a schedule he’s kept for years, although he’s flexible on which days each of those processes occurs. “There are some weeks that I don’t have anybody that comes to the showroom,” he says. “I had a clipboard and took people’s names and numbers for the first month, but that was about it.” The bigger issue is that he has been unable to consistently hire an employee for the shop, although he says he would latch on to a person with the right skillset in a moment, especially considering that he’s now 56 and turning out anywhere from 200 ft² to 500 ft² of product per week. “I brought in two people from the Lower 48, and both times, this wasn’t the place for them,” Turner says. “It didn’t last. I had a guy come up this year for an interview, but he took a job somewhere else.”

“This year I’ve been getting more high-end jobs, but a lot of them are in the $5,000-$7,000 range."

Alec Turner

Weathering the Challenge

Considering that Fairbanks is listed as the coldest large city in the United States, with snow often arriving in September and flurries continuing into May, it’s not a climate that appeals to everyone. Turner describes it as adding a bit of character. Still, he admits that doing installations can be challenging. An important part of that process is his insulated box van which he keeps running so the product stays warm. And, thanks to technology, it isn’t too onerous to move finished pieces. “I have a winch in the van so I can winch big pieces in and out without having to have six people trying to hold onto it,” he says. “I also have ramps, and I bought a No Lift Install System, and I use that a lot.” But automation can only go so far. For that reason, Turner often scouts out jobsites ahead of time because he faces the same problems many others run into doing cold-weather installs. “The biggest challenge in the wintertime is that a lot of people don’t keep their driveways or their walkways clear,” he says. “I’ll actually go and plow the driveway to make sure I can get in. I’ve even snow-blown so I can get a good shot to the back deck so I can get a big piece in.” And, yes, the majority of Turner’s customers are residential. Little of it is what he calls high-end. “Everything is pretty cookie-cutter,” he says. “This year I’ve been getting more high-end jobs, but a lot of them are in the $5,000-$7,000 range. I don’t see too many $15,000-$20,000 jobs. People are more frugal here. We don’t have the large amount of money that some clients do.” Thanks to his location, Turner also does a lot of granite and quartz windowsills. Especially with older windows, the heat indoors and the cold outside can create condensation – to the point that wooden sills just don’t hold up. “It’s kind of a nice touch,” he says. “I just run them on the Fastback to try to make them affordable for the client.” Years ago, he even installed them, although now he’s happy to turn that job over to a contractor or homeowner because, he says, “There’s more to it than I want to get involved with.” As a market, Fairbanks’ location is also self-limiting. The city has approximately 31,000 residents, with the borough (county) taking that number to about 100,000. At this point, Turner has one competitor, but he says most of his sales come from the fact that he’s been in business so long. He also trades out for some radio advertising. The borough is home to three U.S. military installations: Fort Wainwright, Fort Greely, and Eielson Air Force Base. “One of the things about that clientele is they’re usually here from a Southern state where the product they bought for their prior house was $35 ft2,” Turner explains. “They come to me and it’s $135 a ft2.” Alaskan Granite also does some commercial work, often as a subcontractor for casework companies. In years past, Turner says one of his steadiest sources of commercial work was helping refurbish hotel rooms over the winter. “That hasn’t happened since COVID started,” he says. “This was our second summer without any major tourism. I usually do anywhere from 100-200 hotel rooms for everybody from Holland America and Princess Cruises® to locally owned ones.” At the end of October, Turner was also starting work on a medical clinic that he originally planned for July and August. “That job has slowed down as well,” he says. “I honestly think it’s supply-chain problems on their end. Big items like the HVAC units and other mechanical stuff.

"“I’m pretty happy with what I’ve grown, and I’ve grown it all on my own.”

Alec Turner

A Bigger Climb

And that’s saying something, since being near the end of the road in Alaska’s interior makes shipping a costly challenge during the best of times. Early on, Turner only fabricated 2cm slabs because the cost of shipping them was less. Today he’s doing 3cm, but many of his customers have abandoned stone for quartz. “The 3cm is quicker because you don’t have to glue; it takes a lot of processes out of the picture when you move to 3cm,” he says. “The quartz is a market trend. I’d rather work on natural stone but it’s lighter and stronger, and I don’t have the damage that happens to natural stone in the shipping process.” Turner explains that everything he fabricates travels by water from Seattle to Anchorage, and then by truck or rail to Fairbanks. The final cost: about 50 cents a pound. “It can get a little overwhelming,” he says. “If you’re buying 10,000 lbs. worth of stone – 10 slabs – it’s $5,000 to ship, and that adds to the cost. That’s one of our biggest hurdles.” And, yes, Turner has seen prices for shipping go up with supply-chain issues. However, his other big issue is simple availability. “I’ve been running into some issues where the materials haven’t yet been manufactured and it will be Christmas before they’re delivered,” he says. Of course, Turner has always stocked the basics in his showroom. However, he’s not what he describes as a “pushy salesman,” and sometimes customers fail to fall in love with something he has on hand. Changing technology has been as helpful in resolving those issues as it’s been in allowing him to be a one-man stone shop. “A lot of stuff here is done on the Internet,” Turner observes. “They go to a supplier’s website, see if they like anything there, and we communicate back and forth via email. When would you have ever thought you could sell a $20,000 job over a text message?” Naturally, there have been other changes in Turner’s 19 years running Alaskan Granite. For instance, he tries to work “only” 12 hours a day, five days a week, rather than the 14+ hours, six or seven days a week he used to put in. In his free time, he’s fond of climbing big mountains, which included a trip to the top of Mt. Everest in 2009 (a climb featured on the Discovery Channel’s reality series “Everest Beyond the Limit”). “I learned I was good at it and pursued it for quite a few years,” Turner says. “It’s a cultural experience and tests your ability to reach a common goal with other people. But then the business kind of overtook it.” It also allowed him to learn more about stone and the people who work it. “Everywhere I went in the world I would stop at a stone shop or a little quarry or where they were building lodges and hang out,” he says. “It was pretty interesting to see other cultures and how they deal with stone.” As for the business overtaking his other goals and interests, that’s fine, too. Turner is proud of creating what he calls a “small empire” for his family and being independent. He adds that not only is it the longest job he’s ever held, but it provides well for his family and allows them to enjoy Alaska. “I’d like to get a little more automated, but I’ve way above most shops now,” he concludes. “I’m pretty happy with the setup I have and the system I have. Ten years ago, it would have taken me two or three days to do what I can do now in 45 minutes. “I’m pretty happy with what I’ve grown, and I’ve grown it all on my own.”