Fabricator Focus

Precision Granite LLC Pagosa Springs, Colo.

"I’ve tried to focus on more unique things."

All photos courtesy Precision Granite LLC

By K. Schipper

PAGOSA SPRINGS, Colo. – When Andy Hohl started Precision Granite LLC a dozen years ago, he describes this southwestern Colorado community 200 miles southwest of Denver as “a small town, but big enough to support a small granite shop.” in those days, the area was a popular second-home location for Texans looking to escape the summer heat. He admits the early years were sometimes a struggle that required him to get a bit creative growing his business. Automation helped, as has a good team of employees, some of whom have been with him since he opened for business. His business slogan, “The Art of Caring,” extends to them as well as his clients. However, neither his high-end equipment nor a dedicated workforce allowed him to completely contain the chaos created by COVID-19, as people from all parts of the country sought escape to what they saws a safer location. Today, he’s booking jobs four and five months down the road, and has dropped some commercial work that typically got the company through slower times.

“The core of my guys that I had originally are still with me, and that’s really helped the quality of the work. .”

Andy Hohl

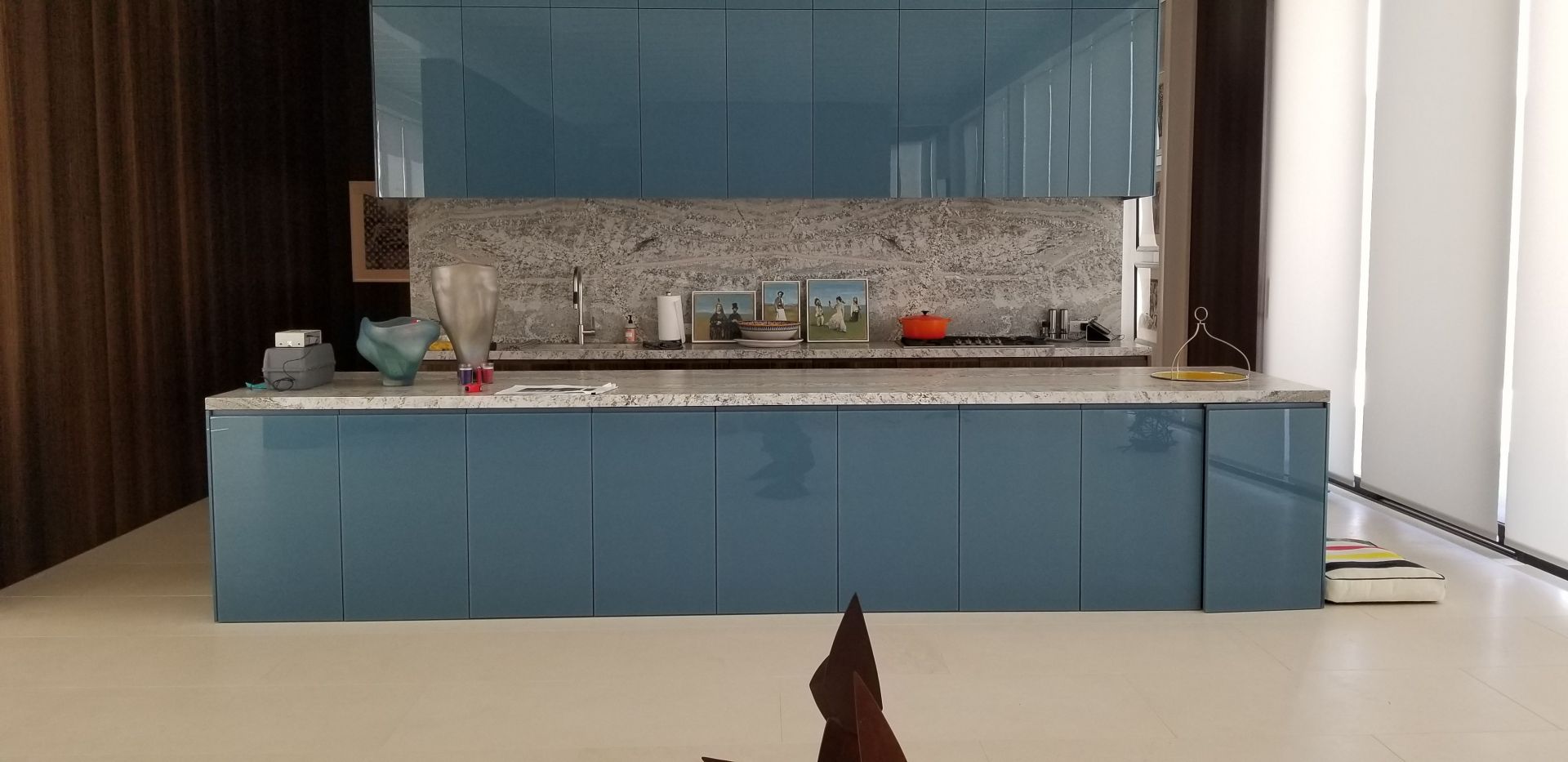

Diverse Directions

An Easterner by birth, Hohl first became acquainted with the countertop industry in the resort community of Telluride, in southwestern Colorado, almost a quarter-century ago. “I was just fixing chips and doing little things at a big hotel they were building there,” he says. “Then, I started working for the fabricator. When he moved to the Durango [Colo.] area, I moved there with that company and continued to work for them. I finally decided to go out on my own 12 years ago.” As with so many other start-ups, Hohl launched his new business with a used saw and hand tools. “I had an old $15,000 Gregori bridge saw, the hand tools and a router,” Hohl says. “I had had a little setup experience because I’d helped moved the shop a couple times with the other company. We did stick templates. We were pretty old-school for the first seven or eight years.” The most old-school aspect of Precision Granite’s early days was the quality of the work the company put out. It truly is “The Art of Caring.” “We’ve always done a really good job,” he says. “The core of my guys that I had originally are still with me, and that’s really helped the quality of the work. And, we have a good reputation for taking care of things when something goes wrong.” Most of what the company does is high-end residential projects. And, until recently, Hohl would supplement his summer income working with another company on one or two large projects in Telluride – basically, celebrity homes. “Some of those projects could equal half the sales we normally did the rest of the year,” he says. “That’s not quite the case now.” He’s also gone in a couple directions not too many fabrication shops emulate. One is to open a granite showroom, Global Stone Imports, in Lake Havasu City, Ariz., which sells slabs wholesale to fabricators in that area – as well as to himself. Hohl explains that four years ago, he and his wife had rented a vacation home there, and while in the area he realized people had to drive 180 miles to either Phoenix or Las Vegas to buy granite. “I have a friend who’s a pretty large importer in Texas and he helped me get going,” Hohl says. “He also has people in Brazil and India, so he helped me get set up to import things from there. I’ve always liked that side of the business; it’s clean and I can grow exponentially without putting on a lot of people.” And, while it’s not going to save his Colorado customers any money, it does give them access to a wide selection of stone they won’t find at the warehouse retailers. “I’ve tried to focus on more unique things,” Hohl says. “I’ve tried to bring in a lot of quartzites and stones that you don’t see every day. That’s our niche; that’s where we shine.” Customers can also shop online at the Global Stone Imports website. Ultimately, Hohl would like to build an addition to his 13,000 ft² showroom and design center in Pagosa Springs to bring some of his Precision Granite slabs indoors, “but that will have to wait until the next downturn because the cost of building is a little bit ridiculous right now.”

“Over the years, I really haven’t found anything that’s as effective as knocking on doors and meeting people and building relationships."

Andy Hohl

Keeping It Clean(er)

His other product line is a bit more common to stone shops: cabinetry. Again, it’s been a profitable decision, made easier by the fact that one of his salespeople (the sales staff numbers six full- and part-time employees, including Hohl) offered cabinetry in his previous business. “I also had the opportunity to know someone who was a cabinet designer,” Hohl says. “She left that for a few years when she had her family, but once she was available to come back to work, she came to work for me.” Hohl says he likes selling cabinetry because it’s much cleaner than something like adding tile where it can take multiple hours to do a three-figure job. “We carry five lines, from the basics to a couple of higher-end lines,” he explains. “They cost anywhere from $5,000 to $40,000, and we normally get the countertops that go along with them. We don’t do any of the installations, but we sell them, receive them, and deliver them, along with dealing with any issues that come up from the shipping and design. “It’s almost like selling slabs,” Hohl adds. “You can grow without having a lot of skilled labor, which is hard to find.” Selling the cabinets also offers another advantage: co-op dollars that he uses to pay for the advertising Precision Granite does on Houzz. Hohl admits it’s about his only paid advertising, although he posts a lot on Google My Business™. “Over the years, I really haven’t found anything that’s as effective as knocking on doors and meeting people and building relationships,” he says. “That’s how I did it down in Arizona. Luckily, my manager there has lived in that community and within the construction industry for 40 years. Knowing everyone is a huge benefit.” The other thing Hohl takes to the bank is Precision’s reputation for simply caring about its customers. “Sure, we make mistakes,” he says. “We’ll replace a kitchen if we have to, or if it’s a misunderstanding, we’ll go the extra mile to take care of everybody. That has come back to pay huge dividends.” At least for now, with jobs booked four and five months ahead, Hohl says his days for traditional advertising are behind him.

"The neatest part of my job now is the family we’ve created with all our employees.”

Andy Hohl

Juggling Act

So how does a company deal with a job list as long as your arm? As Hohl has said, good people help. And, over the years, a commitment to technology has improved on life with the old Gregori and stick templates. “We just upgraded our saw for the second time,” he says. “We’ve got a Sasso K600 Extreme 5-axis bridge saw (which replaced an earlier, smaller and less-powerful model of the same saw). I don’t have a CNC; I’ve found them to be inefficient when you’re focused on quality, as opposed to quantity, and we don’t have a high volume of production. I have a Sasso vertical line polisher, and everything else is done by hand.” He adds that he has a full-time sawyer, and a principal templator, but with so many experienced people in the nine-person shop crew, they’re all familiar with the technology and “they’ve all learned it really well.” Hohl says their accomplishments are such that when mistakes happen it’s almost always because something didn’t get changed in the system, rather than an error in the shop. And that’s certainly not because he hasn’t gone to technology there, too, starting with Moraware software to manage job scheduling and flow. He also abandoned stick templates half a dozen years ago, and currently utilizes a Laser Product Industries LT 55 system. “We went digital even before we had a CNC saw,” Hohl says. “At that time, we were really busy, and I was sending some work to a friend in Denver who would do it and transport it down to me.” Still with most builders in the area booked for at least the next two years, Hohl says the most-honest thing he can do when a client comes in is advise them their job is – at best – three months down the road. “But, after a month, they seem to forget that,” he says. “And everyone has an issue. They’ve sold their house, or they’re closing, or their rental’s running out. There are a million different scenarios. “We try to take a hard line, but we have builders we’ve worked with for years, and customers with big projects. We’ve pre-templated them, but we try to juggle the emergencies along the way.” One thing he has done is cut back on the jobs the company used to take to fill what once were down times. For instance, a local golf resort used to employ Precision Granite to help with the remodeling of about 20 rooms each off-season. “They’re not very profitable, and they hog up the saw with Santa Cecilia and other cheap stones,” Hohl says. “Keeping the saw tied up with production stuff when we could be doing nice residential work really doesn’t make such sense to us.” There are a couple other things Hohl does that are a bit atypical for the industry. For one, templates are done every other week. With everyone trained to do all the jobs in the shop, even on that schedule, sending someone out tends to disrupt the workflow. “We just knock out the templates we need to knock out,” he explains. He also doesn’t have a designated installation crew. Part of that stems from the fact that the guys who started with him when they were in their twenties are now older. “Everything is relatively close to our shop,” Hohl adds. “We’ll send out a small crew for the small stuff, but we’ll send everybody for bigger things, whether that’s big islands or complicated jobs. We knock them out and are done with them and come back to the shop and go to work on the next one.” And, when Hohl says “everybody,” he means it. While he puts in time in the office, Hohl can also be found in the shop or out on installs. “I’m still in all aspects of it,” he says. “Other than the builders, there are many people who don’t know I’m the owner.” Still, Hohl takes a lot of pleasure from being the owner of Precision Granite. For one thing, he says after years of struggling, it’s nice to be finally over that initial hump. “The neatest part of my job now is the family we’ve created with all our employees,” he says. “Being able to keep everybody and watch them grow, and get houses and have children, learn and move up in the world.” And, while he appreciates the freedom to make the decisions, his greatest success is taking the business beyond where he thought it would go while still treating everyone with respect. Ultimately, it goes back to “The Art of Caring.” “That covers all aspects of it,” he concludes. “Everybody has a perspective – the customer, the employees, the business. It’s important to understand all those things and respect them. That’s how we’ve tried to approach everything.”