Take Care With the Air

It Doesn't Take Much Pressure to Inflate Major Hazards

Compressed air and compressed air systems present potential workplace hazards. Air power is essential for plenty of fabrication machines in a stone shop, but be aware of the risks involved with compressed air and always use it safely.

Compressed air can damage eyes, eardrums, or get into your body. This can occur at pressures as low as 20 to 25 psi. Never underestimate its potential for causing injury.

From the OSHA Files

Employee #1 and a coworker, both maintenance personnel, were performing maintenance on a backup compressor. The switch on the compressor in use did not shut off. The built-up pressure released explosively, killing Employee #1 and injuring the coworker.

Investigators found that the compressor had no pressure relief valve to relieve pressure or prevent pressure from building up.

Moreover, there was no procedure in place to check valves periodically. The company did not have a written preventative maintenance program.

This case is representative of injuries caused by improper work practices. No special emphasis or priority is implied nor is the case necessarily a recent occurrence. The legal aspects of the incident have been resolved, and the case is now closed.

OSHA Prevention Recommendations

- Procedures shall be developed, documented and utilized for the control of potentially hazardous energy (lock out/ tag out).

- Equip all air receivers with a readily visible indicating pressure gauge and with one or more spring-loaded safety valves. The total relieving capacity of such safety valves shall be rated at more than 10% of the maximum allowable working pressure of the receiver.

- All safety valves must be tested frequently and at regular intervals to determine whether they are in good operating condition.

- A competent person must perform periodic inspections of all operating equipment.

- The employer must initiate and maintain a safety and health program.

Full explosive decompression can take a chunk out of a wall ... or a person. Don't take equipment for granted.

• Air in excess of 30 psi can blow an eye out of its socket or rupture an eardrum.

• Compressed entering a body opening can burst internal organs, leading to an agonizing death.

• Air pressure can cause internal bleeding and intense pain.

General Air Safety

There are several guidelines to follow before grabbing an air hose:

- First of all, make sure it’s an airline you’re trying to tap into. Fittings and valves look different, but sometimes lines cross or ‘disappear’ into a wall. Take time to make sure.

- Make sure the hose is in good condition.

- All pipes, hoses and fittings must have, at a minimum, the rating of the maximum pressure of the compressor. Compressed air pipelines should be labeled as to maximum working pressure in pounds-per-square-inch (psi).

- Air supply shutoff valves should be located (as nearly as possible) at the point of operation.

- Air hoses should be kept free of grease and oil to reduce the possibility of deterioration.

- Hoses should not be strung across floors or aisles where they may cause people to trip and fall. When possible, air supply hoses should be suspended overhead or otherwise located to afford efficient access and protection against damage.

- Hose ends must be secured to prevent whipping if an accidental cut or break occurs.

- Pneumatic-impact tools, such as nail guns, should never be pointed at another person.

- Before a pneumatic tool is disconnected, unless it has quick-disconnect plugs, the air supply must be turned off at the control valve and pressure at the tool should be bled.

- Never use compressed air to clean dirt and dust from clothing or a person’s skin.

- Use water or vacuum for cleaning stone dust.

- Static electricity can be generated through the use of pneumatic tools. This type of equipment must be grounded or bonded if it is used where fuel, flammable vapors or explosive atmospheres are present.

Remember: Safety is the responsibility of management and employees!

All Natural Stone Institute safety resources and courses are available free of charge at www.uofstone.org and www.naturalstoneinstitute.org/safety.

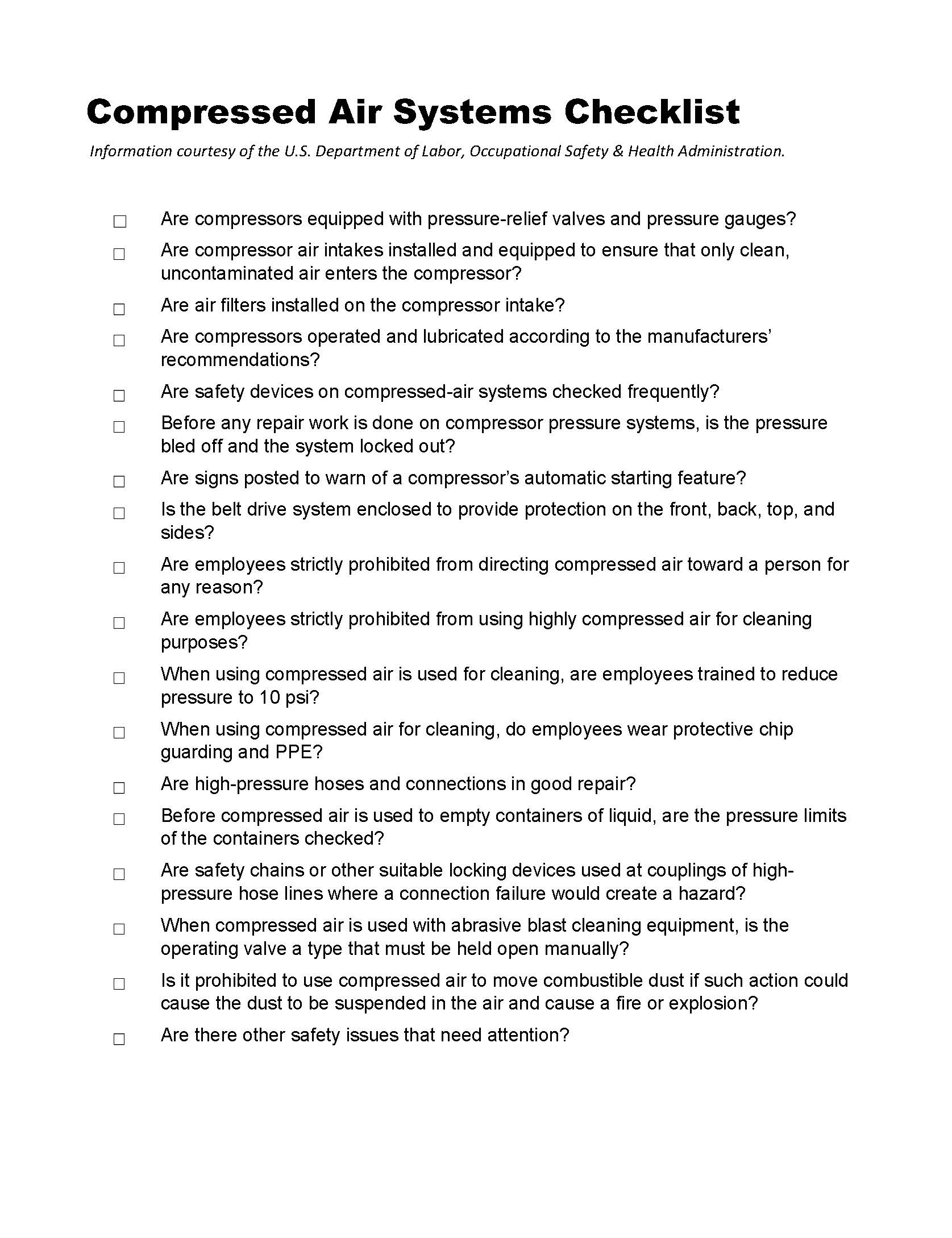

Here's a handy checklist to help make sure you're covering the bases with compressed-air safety, courtesy of OSHA at the federal level, along with Oregon's state OSHA.

If you're not up to trying a screen or image capture for the checklist -- or, in the case of smartphone readers, the text is too small to read, email the editor at emerson@stonemag.com and he'll send you a PDF.

The information herein is provided by the Natural Stone Institute as a general summary for use in job site toolbox talks and is provided to augment and not substitute for or replace required training under any applicable local, state or federal workplace statute, law or regulation. It is the user’s responsibility to ensure this content is consistent with job site requirements and applicable statutes, laws or regulations prior to use and make any required additions or changes.